Frequently Asked Questions

You can find answers to the most commonly asked questions about Sandrin Knives below.

It depends on what you cut but on average a Sandrin Knife will retain its razor-sharp edge on average 10 times longer than steel knives.

The maintenance of an edge is directly related to how a knife is used. Nothing lasts forever, but a Sandrin comes close.

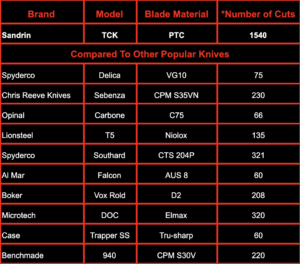

According to independent testing, our proprietary blades will stay sharp from 5 to 26 times longer than these popular knives.

*Cedric and Ada Outdoor Gear Reviews

Polyhedral Tungsten Carbide (PTC) was invented by Sandrin founder, Alessandro Colombatto and his team. A second-generation tungsten carbide artisan, Alessandro and his parent company, Turmond, have been pushing the Tungsten Carbide industry boundaries for four decades. An established leader in tungsten carbide blades used for high-speed cutting applications, Alessandro has developed industrial cutting solutions for 21 different industries.

PTC is composed of tungsten carbide and cobalt along with binder elements that have been used for decades in a variety of industrial applications, for example, crafting superior steel-cutting tools. However, traditional grades of tungsten carbide are brittle, so creating a durable knife blade from this material was previously thought to be impossible. Sandrin’s patented flexible PTC has solved this problem. In fact, our blades are so hard you can use the back edge of a Sandrin to sharpen traditional steel knives.

The physical properties of PTC fall in between the properties of ceramic and steel. Ceramic is harder than polyhedral tungsten carbide but very brittle. Steel is less hard than TC but has good bendable properties. PTC is about 30% to 50% harder than steel with similar cutting properties as ceramic. A Sandrin blade has a weight of about twice that of a steel blade and a density similar to gold.

Sandrin knives are designed for cutting and slicing. Sandrin knives are NOT prying or chopping instruments.

The Sandrin knife has a hardness as measured in Rockwell at HRC71. Most steel knives have a Rockwell hardness in the 50’s, while the hardest knives are in the 62 to 64 HRC range. Mythical levels of knife level hardness have been reportedly achieved by one company at 67 HRC. Sandrin Knives are truly in their own class in terms of a durable cutting edge.

The famed Fibonacci sequence inspires the five precisely placed holes in the blade. Discovered in the thirteenth century by Leonardo of Pisa (better known as Fibonacci), it is a series of numbers which forms a seemingly divine sequence that appears recurrently in nature and other beautiful things. Fibonacci’s numerical pattern has fascinated mathematicians, scientists, and artists for centuries.

Sandrin Knives warrants to you, the original purchaser, that a knife was manufactured free of defects in material or workmanship; and for a period of 30 days from receipt of purchase, the manufacturer agrees to correct your tungsten carbide knife by repair or replacement (with the same or comparable quality model). Sandrin Knives reserves the right to inspect, examine, and/or test the knife to assess any claim made. This warranty is void if the knife has been abused, misused, damaged by accident. This warranty does not apply to normal wear and is void if any unauthorized repair and/or alteration has been performed on the knife